Fraud can quietly erode the financial health of a business—especially in manufacturing, where...

Cybersecurity and Fraud in Manufacturing: What Every CFO and Operations Leader Must Know

In today’s connected production environments, cybersecurity is no longer an IT problem — it's a serious operational and financial risk. From ransomware attacks that halt production lines to internal fraud schemes that drain budgets, manufacturers face unique vulnerabilities that traditional controls alone can’t handle.

This blog explores how cyber threats and fraud impact manufacturing businesses and outlines clear, finance-informed strategies to protect your operations, data, and capital.

Why Manufacturing Is a Prime Target

Modern manufacturing relies heavily on integrated systems — ERP platforms, cloud-based supply chains, connected machinery, and remote access tools. This operational complexity creates numerous entry points for bad actors.

Key reasons manufacturers are vulnerable:

- Legacy systems with weak access controls

- Minimal investment in cybersecurity relative to other sectors

- High-value proprietary data (formulas, CAD files, pricing models)

- Extended third-party supply chains with shared platforms

In fact, many manufacturers don’t realize how exposed they are until they suffer a breach — often at a staggering cost in downtime, ransom payments, legal fees, and reputation damage.

Real-World Impact: Case Example

In 2021, a global auto parts supplier experienced a devastating ransomware attack that encrypted their entire ERP system. The result? Eight days of halted production, $10 million in lost output, a steep ransom payout, and months of vendor contract renegotiations due to missed deadlines. This wasn’t an outlier — it's a scenario playing out across the manufacturing sector with increasing frequency.

The Hidden Cost of Cybercrime in Production

A single ransomware event can halt production for days. According to industry studies, the average downtime after a cyberattack exceeds 22 days, often costing manufacturers millions in lost output and emergency recovery.

Beyond production stoppage, cybercrime can lead to:

- Compromised intellectual property

- Vendor trust issues

- Legal and compliance violations

- Reputational damage with customers and investors

These risks also impact financial forecasting and capital allocation. If cybersecurity investments are neglected, it can delay or derail future expansion. Smart companies now factor cyber resilience directly into their capital planning strategies.

Cybersecurity as a Valuation Driver

For manufacturers looking to grow, raise capital, or prepare for sale, cybersecurity posture directly affects business valuation. Investors and acquirers scrutinize risk controls just as closely as revenue or EBITDA.

Cyber resilience contributes to:

- Lower cyber insurance premiums

- Favorable audit results

- Increased attractiveness in M&A deals

- Reduced exposure to litigation

Think of security investment not as a cost center, but as a driver of business continuity and valuation. Clean internal controls and secure ERP systems are as important as balance sheets when preparing for strategic events.

The Overlooked Risk: IT and OT Integration

Many manufacturers are increasingly vulnerable due to the convergence of IT (Information Technology) and OT (Operational Technology). Shop floor machinery — like programmable logic controllers (PLCs), CNC machines, and SCADA systems — are often connected to networks and cloud-based ERP platforms for monitoring and data reporting.

This IT/OT integration creates dangerous new attack surfaces. A hacker gaining access to your business network could potentially move laterally into the control systems operating your machines, disrupting production, damaging equipment, or even triggering unsafe conditions.

Key vulnerabilities in OT systems include:

- Default admin passwords left unchanged

- Lack of software updates or patches

- Outdated network segmentation

- Remote desktop access tools with poor security

This is why ERP system selection must be coupled with robust cybersecurity evaluation. It’s no longer enough for a platform to be functional — it must be secure.

Financial Fraud Risks Inside Manufacturing

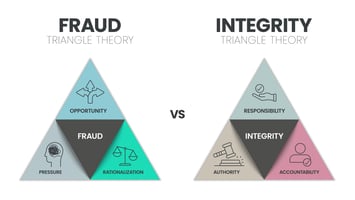

Cyber threats aren’t the only danger. Financial fraud remains a major concern — particularly when internal controls are outdated or misaligned.

Common types of fraud in manufacturing include:

- Vendor overbilling or duplicate payments

- Falsified inventory or asset write-offs

- Unauthorized bonus or payroll manipulation

- Fictitious vendor setups or check tampering

A strong fraud prevention framework includes financial controls, staff accountability, clear segregation of duties, and oversight from finance leadership.

Regulatory and Compliance Risk: The Standards That Matter

If your manufacturing business operates in aerospace, defense, or exports internationally, you're likely subject to strict cybersecurity compliance requirements. Failing to meet these can disqualify you from lucrative contracts and expose your company to penalties.

Key standards include:

- CMMC (Cybersecurity Maturity Model Certification) – Required for Department of Defense contracts

- NIST SP 800-171 – Federal information protection for contractors

- ISO/IEC 27001 – Global standard for information security management

If your firm bids on federal or defense contracts, frameworks like CMMC or NIST SP 800-171 may require enforced cybersecurity protocols — a compliance gap could cost future revenue.

Building compliance into your internal controls supports clean audits, improved client confidence, and long-term revenue protection. It also reinforces your financial risk management plan.

Aligning Cybersecurity with Finance Strategy

The most effective approach to security in manufacturing blends operational controls with financial oversight. Key steps include:

1. Treat cybersecurity as a financial function

Involve your CFO and controller in cybersecurity budgeting and planning. This ensures alignment with broader risk management and ROI metrics.

2. Conduct a financial risk assessment

Review how a breach would affect production revenue, supply chain contracts, and customer retention. Tie this directly into your rolling forecasts.

3. Audit your ERP and data access

Many breaches stem from lax access controls within core financial systems. Secure your ERP with multifactor authentication and role-based access.

4. Train all staff — not just IT

Every team member with system access is part of your cybersecurity perimeter. Provide ongoing training to manufacturing, admin, and finance teams.

5. Build response plans

Have a documented incident response plan that includes who to contact, how to isolate infected systems, and how to maintain communication.

Fraud Prevention as a Growth Enabler

Fraud detection isn’t just defensive — it also supports growth. Manufacturers with strong internal controls and fraud resilience are more attractive to lenders, partners, and acquirers.

In fact, a clear fraud framework can:

- Support better financial audits

- Improve investor confidence

- Boost operational KPIs

- Protect expansion plans

If your goal is to scale profitably, fraud prevention is essential. It ensures every dollar spent on inventory, payroll, or equipment produces value.

Actionable Takeaways for Manufacturing Leaders

Here are practical next steps:

- Perform a cybersecurity audit of all production and financial systems

- Implement two-person approval rules for high-risk transactions

- Secure your ERP and payroll systems with updated credentials

- Evaluate your cybersecurity insurance policy

- Align your IT, finance, and operations teams for integrated planning

- Reference standards like CMMC and NIST when planning internal controls

- Review ERP selection criteria to ensure cybersecurity integration

- Revisit cost impacts of downtime with this guide on production disruptions

Conclusion: Secure Systems Drive Confident Growth

Cybersecurity and fraud prevention aren’t just about avoiding worst-case scenarios — they’re critical tools for building operational resilience and long-term financial performance.

If your manufacturing company is looking to modernize operations, invest in ERP, or expand production, make sure your security strategy scales with you. The cost of inaction is far greater than the price of proactive protection.

Need help assessing your financial controls or cybersecurity alignment? Accounovation can help your team design systems that protect margins, IP, and future growth.